What does mechanics do?

Mechanics is all about fostering the imagination of young engineers. We prioritize

simplicity in our designs - not only does this make our process accessible to new

members but it's critical for allowing us to resolve our issues efficiently. We utilize

design software like CAD to plan our robot chassis designs to ensure our time is spent

well.

The Robot Design Process

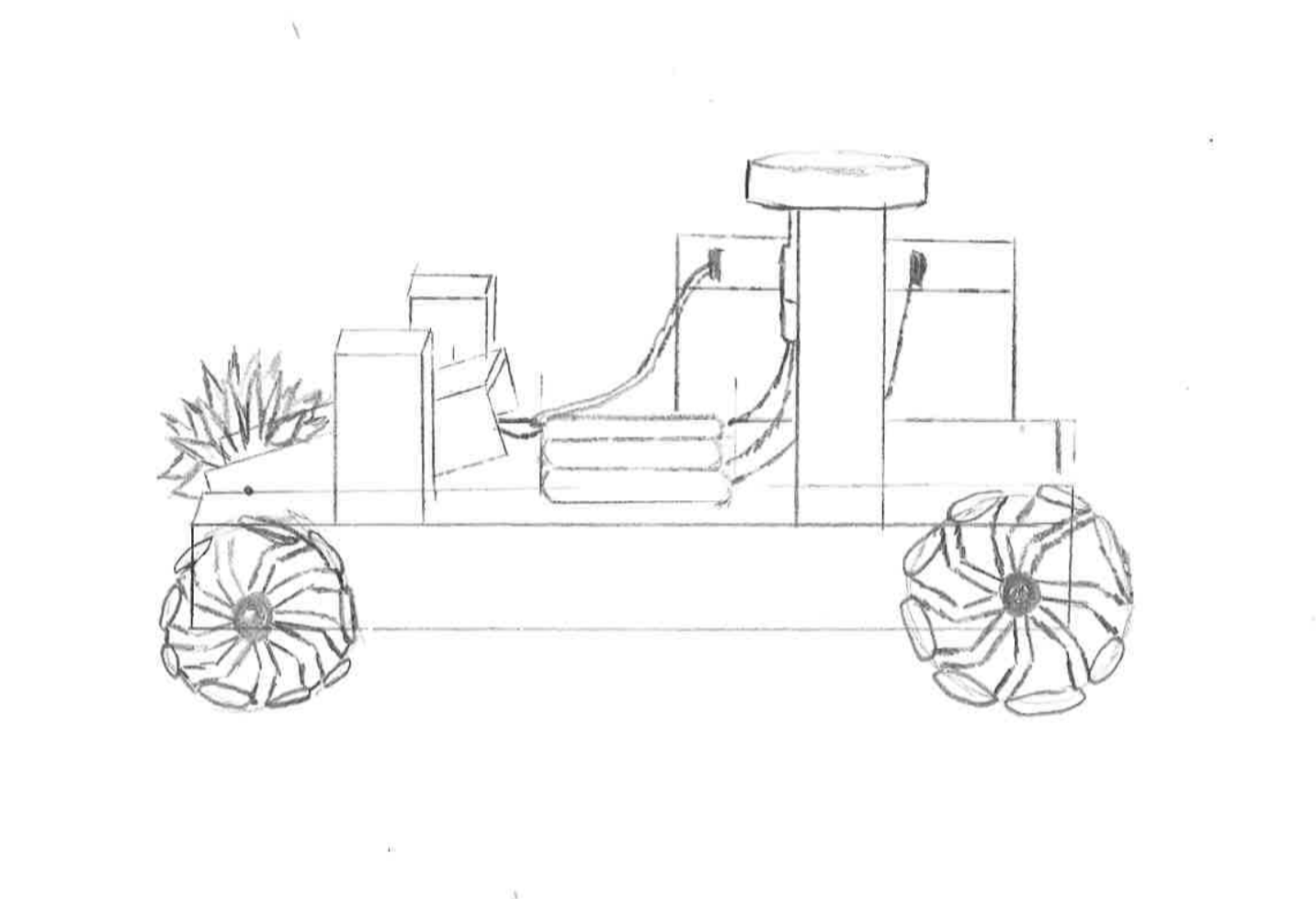

Starting from sketch

Every year, the challenge changes. While some parts of the robot stay the same

year-over-year, most of the parts change. However, before we can start putting parts

together we need to sketch out what we want the robot to look like.

Sketch by Griffin Rho ('24).

Sketch by Griffin Rho ('24).

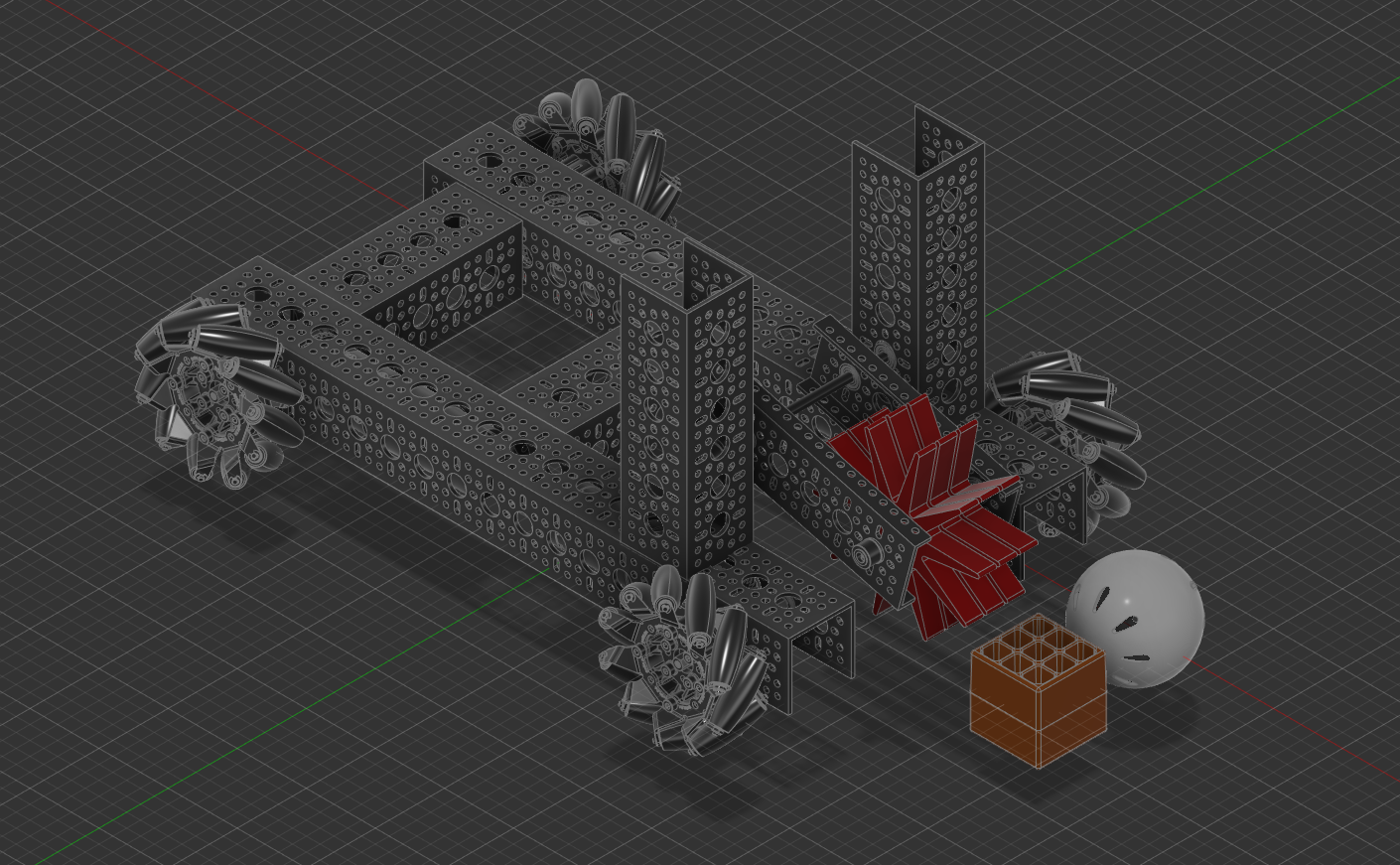

CAD Design Process

Once our sketch has been semi-finalized, we begin the Computer Aided-Design (CAD)

process. We use Fusion 360 to create a 3D model of our sketch.

CAD created by Mihir Patil ('22), Alex William ('23) and Gautam Soni ('23).

CAD created by Mihir Patil ('22), Alex William ('23) and Gautam Soni ('23).

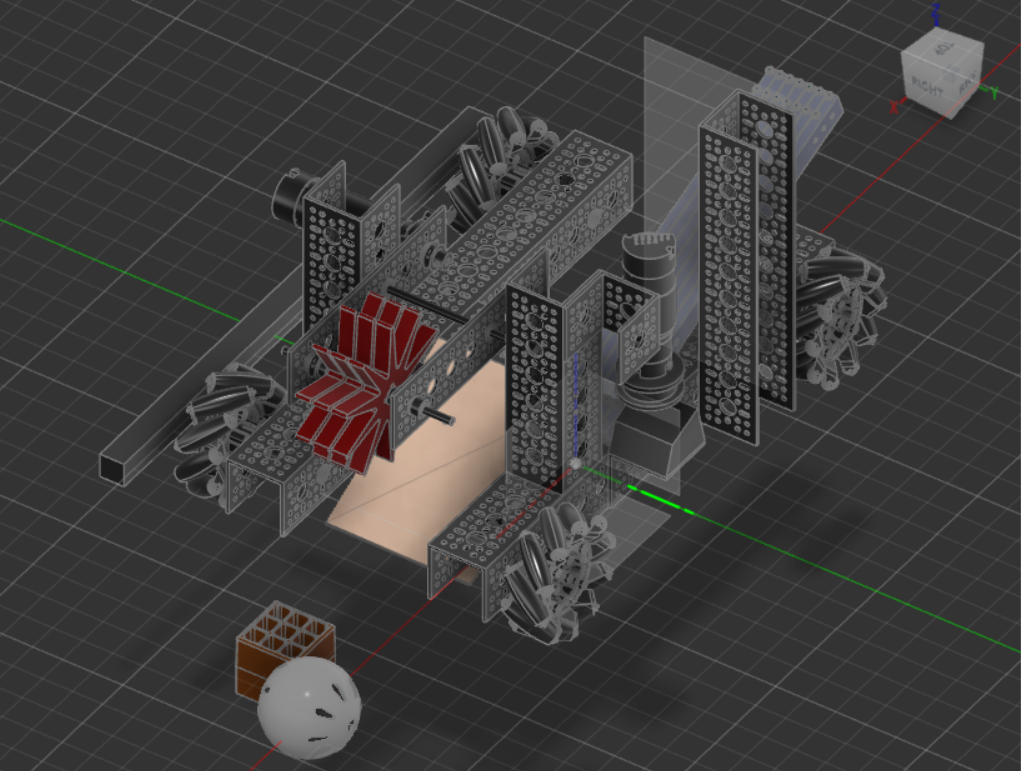

Evolving Designs

Our CAD design is never truly finished. It is constantly evolving throughout the year as we recognize missing

features and add new ones. These new features can range from support rods to a 3D printed ramp.

CAD created by Alex William ('23) and Gautam Soni ('23).

CAD created by Alex William ('23) and Gautam Soni ('23).

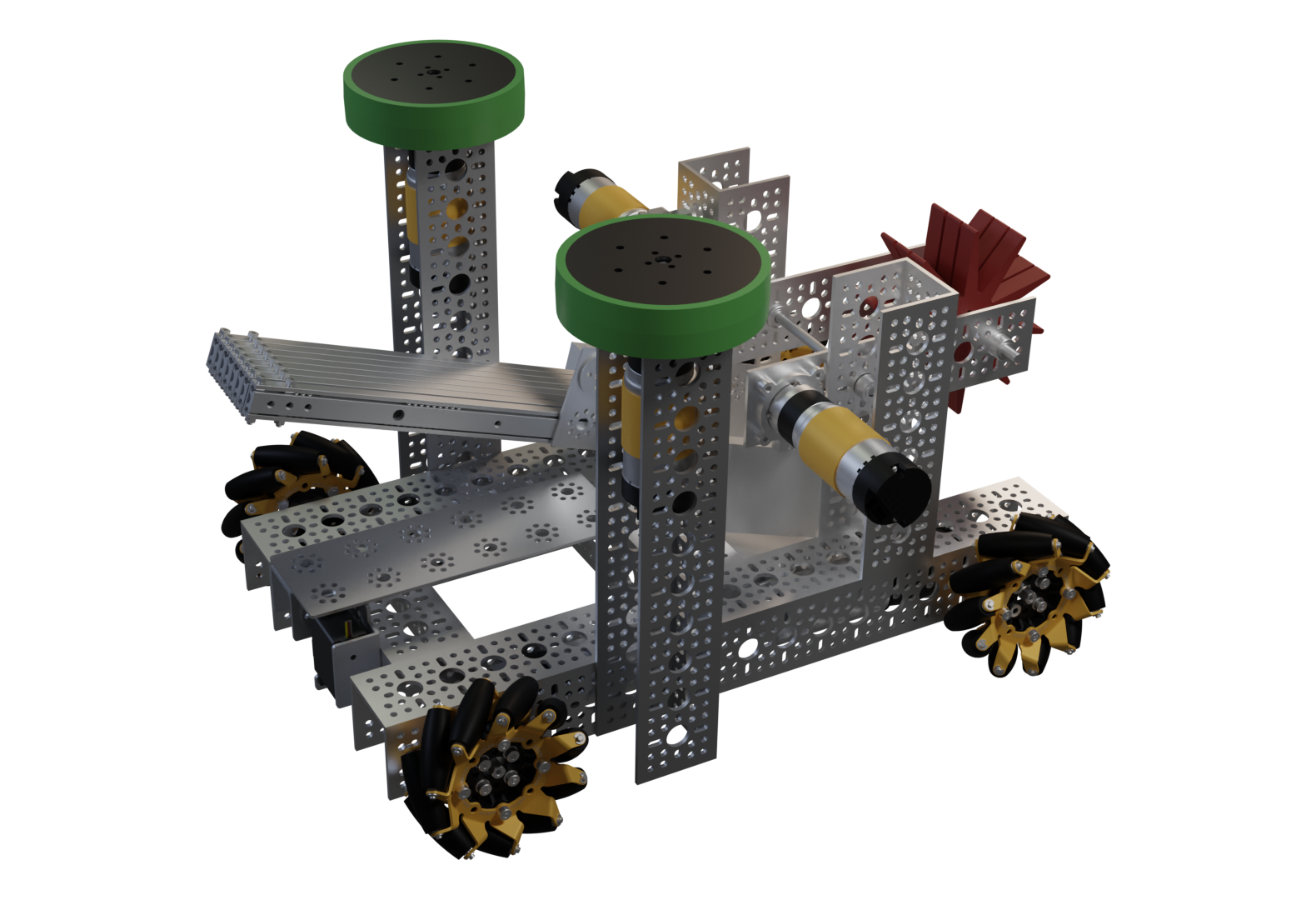

A simple render

Once we have a solid design, we begin the render process. This allows us to bring our

robot to life, allowing us to see what it is going to look like in the real world.

Render created by Alex William ('23) and Gautam Soni ('23).

Render created by Alex William ('23) and Gautam Soni ('23).

The final look

After hours of design, interation, testing, and more testing, the final look of the robot comes alives. This

final version the combined result of over a dozen members, not just in Mechanics, but in all of our teams.

Render created by Mihir Patil ('22).

Render created by Mihir Patil ('22).